Kat and Larry Stokes of Austin’s Korman Fine Jewelry Share Their Story Of A Korman Diamond

The Fabled Continent

Serving as the border between South Africa and Namibia, the Orange River is where every Grandview Klein Diamond’s story begins. Millions of years ago, volcanic eruptions in the Kimberly area of South Africa brought these rough diamonds to the earth’s surface through a type of magma known as kimberlite. The river flowed with diamonds, carrying them downstream and depositing them in the sandy sea bottom in the mouth of the river. Today, using satellite imagery and innovations in marine diamond vessels, thousands of rough diamonds are mined each year in the old riverbed, and mining has become Namibia’s leading economic sector, serving Namibian communities both socially and economically. Recently, Austin’s Korman Fine Jewelry owners Kat and Larry Stokes, who hail from Tyler, Texas, traveled to Namibia on an educational trip to view the Namibian diamond mining process each step of the way…and are excited to share their first-hand experience with their clients.

A young democratic nation, Namibia strives to utilize its resources to uplift their people. Through their partnership with De Beers Diamond Company (known as NamDeb), they’ve created the most sustainable and technologically advanced marine mining vessel in the world, the Benguela Gem. Commissioned in March 2022 and operating 24 hours a day, 365 days a year, it is expected to mine over 600,000 gem quality diamonds along the coast. The vessels’ 28,000 ton crawler combs the ocean floor, allowing the rough diamonds to travel through a buoyant tube into the sorting processor, instantly spitting back out non-diamond remains. Fortunately, there isn’t any coral or significant marine wildlife residing in the mining area, and the vessel only operates within a depth of 140 ft in the ocean floor, avoiding any drilling in the bedrock.

From the processor, the rough diamonds are transported into a “hands off” zone, operating completely without human assistance. They centrifuge the rough diamonds out of the material, then run it through a fluorescent machine before transporting them via helicopter to shore. With six marine mining vessels, they have completely shifted Namibia’s overall diamond yield. Previously sourcing 95% through land mining in the early nineties, 70% of their diamond yield now comes from marine mining today. With a designated 6,000 sq km of Namibian coast to mine at a rate of 15 sq km annually, the country produces top, gem quality diamonds ranging from 0.10cts to 100ct pieces of rough.

Bound For Diamonds

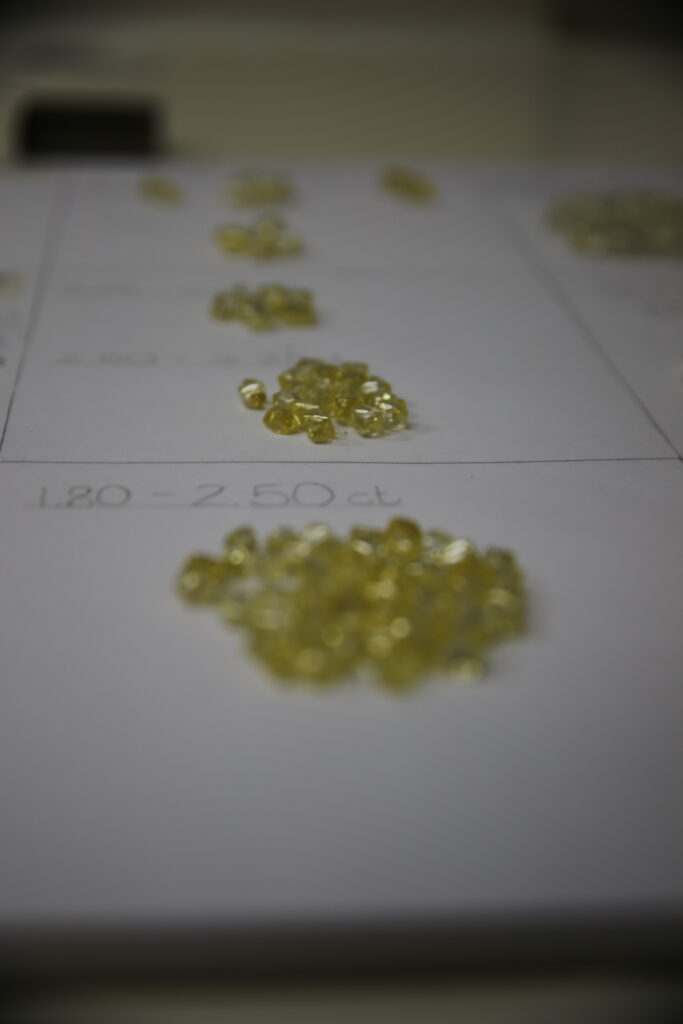

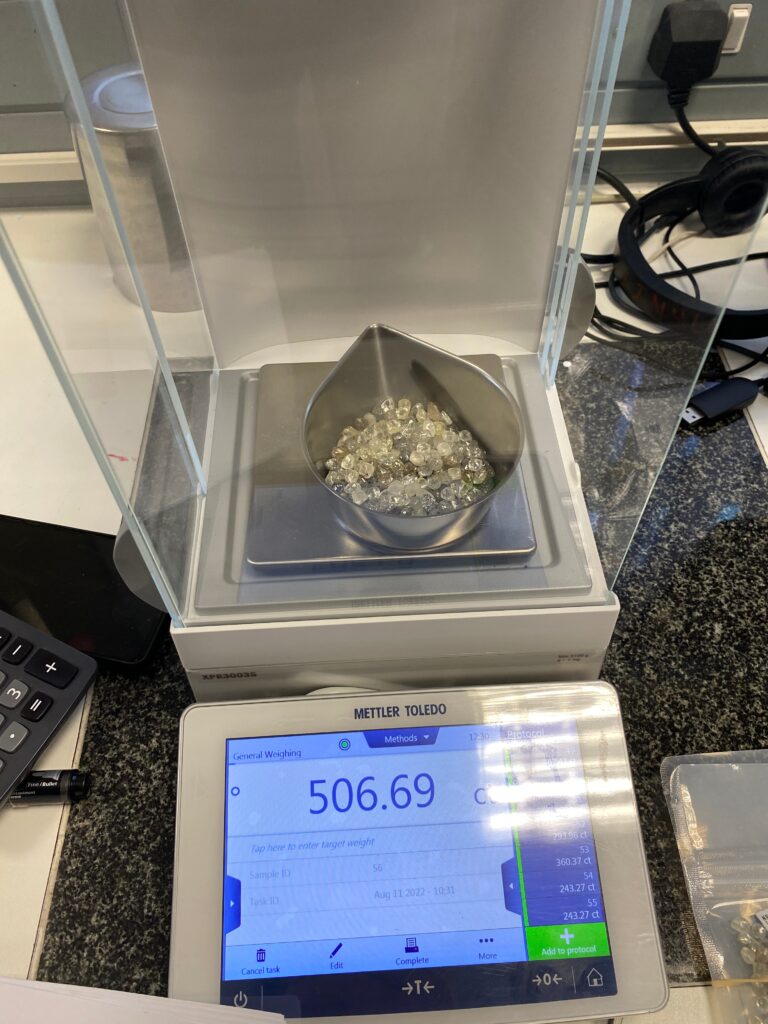

After being transported to Windhoek, the rough diamonds are sorted, valued, and sold through the Namibian Diamond Trading Center, (NDTC), employing around 100 experts in their field, who clean, sort, weigh, and value each diamond. The diamonds are first cleaned in an acid bath to wash off any excess buildup and confirm their exact weight. The sorting begins here, as they carefully organize them according to size and varying color grades. Specialty machines assign a value to each lot before distributing them among the 11 sight holders committed to buying their lot every month, including Korman’s partner, Grandview Klein Diamonds. The profits are split 50/50 between DeBeers and the Namibian government.

Grandview Klein began its partnership as one of the first with NDTC in 2007, and currently employs around 50 people in its facility in Windhoek. The diamonds go through many phases in the process of turning into a perfectly cut stone. The first machine the rough diamond enters tests fluorescence, then they put the stone into The Galaxy machine. An NDA is required to view the inside of The Galaxy, which maps the stone completely, identifying any naturals in the stone that may be an issue during cutting. They then use a laser to cut away the smallest amount possible while enhancing the natural characteristics of the stone. For every 100cts of rough, they yield about 40-50ct in gem cut, quality stones. Each seat is very specialized, one responsible for cutting the facets, another the girdle, etc. There are no more than six expert cutters in each room, as each cut is recorded and executed with precision. Finally, the cut diamonds are polished and tested for all characteristics they planned for, to ensure optimal quality, before they are purchased by partnered retailers like Korman.

Giving Back

With factories and operations in Namibia, Botswana, and South Africa, Grandview Klein Diamonds has become the largest diamond manufacturer in the U.S. and the supplier of the quality diamonds you see at Korman. Their core values of craftsmanship, trust, dedication, and integrity allow them to support the industries and communities in which they do business, inspiring others to do the same.

Korman is proud to stand with Grandview Klein in their mission to give back to the communities that have given so much to our own. In addition to supporting Namibia and South Africa through the purchase of rough diamonds and employment of local citizens, Grandview Klein and Korman are committed to giving back to the communities in a myriad of ways. During their recent trip, the Stokes had the privilege of meeting some of the students from the Eros Primary school in Windhoek, and make substantial donations to their educational fund, providing scholarships and supplies to young girls. In addition, Grandview Klein and their retail partners collectively purchased three dialysis machines and donated them to a clinic in a low income area of Windhoek where the need is great, and diets are poor. Every diamond has a story, and this is only where it begins. The rest is written from the special moment that you find the perfect piece for you, and on to generations to come.

For all your fine jewelry shopping needs, visit Korman Fine Jewelry in Austin.